The Role of Ceramic Resistor Products in Practical Applications

I. Introduction

In the world of electronics, resistors play a crucial role in controlling the flow of electric current. Among the various types of resistors, ceramic resistors have gained significant attention due to their unique properties and versatility. Ceramic resistors are made from a combination of ceramic materials and conductive elements, providing a reliable solution for a wide range of applications. This blog post will explore the role of ceramic resistor products in practical applications, highlighting their types, properties, advantages, challenges, and future trends.

II. Types of Ceramic Resistors

A. Composition and Manufacturing Process

Ceramic resistors are primarily composed of ceramic substrates, which provide electrical insulation and mechanical stability. The conductive materials, often metal oxides or carbon-based compounds, are applied to the ceramic substrate using various production techniques.

1. **Materials Used**: The choice of materials is critical in determining the performance characteristics of ceramic resistors. Common materials include alumina, which offers excellent thermal stability, and various conductive materials that ensure effective current flow.

2. **Production Techniques**: The manufacturing process for ceramic resistors typically involves screen printing and thick film technology. In screen printing, a paste containing conductive materials is applied to the ceramic substrate, followed by a firing process that solidifies the resistor. Thick film technology allows for the creation of resistors with precise resistance values and tolerances.

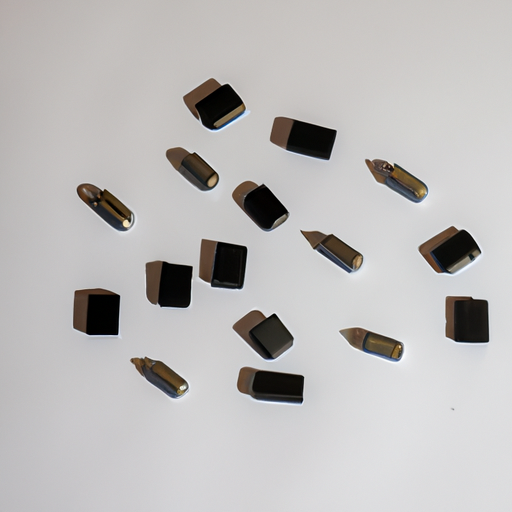

B. Varieties of Ceramic Resistors

Ceramic resistors come in several varieties, each designed for specific applications:

1. **Thick Film Resistors**: These resistors are characterized by their thick conductive layer, making them suitable for high-power applications. They offer good stability and are widely used in consumer electronics.

2. **Thin Film Resistors**: With a thinner conductive layer, thin film resistors provide higher precision and lower noise levels. They are often used in applications requiring high accuracy, such as medical devices and instrumentation.

3. **Power Resistors**: Designed to handle high power levels, power resistors are essential in applications like motor drives and power electronics. Their robust construction allows them to dissipate heat effectively.

4. **Specialty Resistors**: This category includes high-voltage and high-temperature resistors, which are tailored for specific environments and conditions, such as automotive and aerospace applications.

III. Key Properties of Ceramic Resistors

A. Electrical Properties

1. **Resistance Values and Tolerance**: Ceramic resistors are available in a wide range of resistance values, allowing designers to select the appropriate resistor for their specific needs. The tolerance levels can vary, providing flexibility in circuit design.

2. **Temperature Coefficient of Resistance (TCR)**: The TCR indicates how much the resistance changes with temperature. Ceramic resistors typically exhibit low TCR values, ensuring stable performance across varying temperatures.

B. Thermal Properties

1. **Heat Dissipation Capabilities**: One of the standout features of ceramic resistors is their ability to dissipate heat effectively. This property is crucial in preventing overheating and ensuring the longevity of electronic devices.

2. **Thermal Stability**: Ceramic materials are inherently stable at high temperatures, making ceramic resistors suitable for applications in harsh environments.

C. Mechanical Properties

1. **Durability and Reliability**: Ceramic resistors are known for their robustness and resistance to mechanical stress. This durability makes them ideal for use in demanding applications.

2. **Resistance to Environmental Factors**: Ceramic resistors can withstand various environmental conditions, including humidity and extreme temperatures, ensuring reliable performance in diverse settings.

IV. Applications of Ceramic Resistors

A. Consumer Electronics

Ceramic resistors are widely used in consumer electronics, including smartphones, tablets, and computers. They play a vital role in managing power distribution and signal processing, contributing to the overall performance and efficiency of these devices. Additionally, they are found in audio equipment and home appliances, where they help maintain sound quality and energy efficiency.

B. Industrial Applications

In industrial settings, ceramic resistors are essential components in automation and control systems. They are used in power electronics and motor drives, where their ability to handle high power levels and dissipate heat is critical for operational efficiency.

C. Automotive Industry

The automotive industry has increasingly adopted ceramic resistors, particularly in electric vehicles and hybrid systems. These resistors are integral to safety and control systems, ensuring reliable performance in demanding conditions. Their durability and thermal stability make them suitable for use in various automotive applications.

D. Medical Devices

In the medical field, ceramic resistors are crucial for diagnostic and monitoring equipment. Their precision and reliability are essential for accurate measurements. Additionally, they are used in implantable devices, where stability and biocompatibility are paramount.

E. Telecommunications

Ceramic resistors play a significant role in telecommunications, particularly in signal processing and transmission. They are used in networking equipment, where their ability to maintain performance under varying conditions is essential for reliable communication.

V. Advantages of Ceramic Resistors

Ceramic resistors offer several advantages that make them a preferred choice in various applications:

A. High Stability and Reliability

Ceramic resistors are known for their stability over time, ensuring consistent performance in electronic circuits. Their reliability reduces the risk of failure, making them ideal for critical applications.

B. Wide Range of Resistance Values

The availability of ceramic resistors in a broad range of resistance values allows designers to select the most suitable component for their specific needs, enhancing design flexibility.

C. Excellent Thermal Management

The ability of ceramic resistors to dissipate heat effectively contributes to the overall thermal management of electronic devices, preventing overheating and extending their lifespan.

D. Compact Size and Lightweight Design

Ceramic resistors are typically compact and lightweight, making them suitable for modern electronic devices that prioritize space and weight efficiency.

E. Cost-Effectiveness in Mass Production

The manufacturing processes for ceramic resistors allow for cost-effective mass production, making them an economical choice for various applications.

VI. Challenges and Limitations

Despite their many advantages, ceramic resistors also face certain challenges and limitations:

A. Sensitivity to Mechanical Stress

While ceramic resistors are durable, they can be sensitive to mechanical stress, which may lead to cracking or failure in extreme conditions.

B. Limitations in High-Frequency Applications

Ceramic resistors may not perform optimally in high-frequency applications due to parasitic capacitance and inductance, which can affect signal integrity.

C. Potential for Thermal Runaway in Certain Conditions

In specific scenarios, ceramic resistors may experience thermal runaway, where an increase in temperature leads to a further increase in current, potentially causing failure.

VII. Future Trends and Innovations

The field of ceramic resistors is evolving, with several trends and innovations on the horizon:

A. Advances in Materials Science

Research into new materials is paving the way for the development of ceramic resistors with enhanced properties, such as improved thermal stability and lower TCR values.

B. Development of New Manufacturing Techniques

Innovations in manufacturing processes are expected to lead to more efficient production methods, reducing costs and improving the quality of ceramic resistors.

C. Integration with Smart Technologies

As the Internet of Things (IoT) continues to grow, ceramic resistors are likely to be integrated into smart technologies, enabling more efficient and responsive electronic devices.

D. Sustainability and Eco-Friendly Practices

The push for sustainability in manufacturing is leading to the exploration of eco-friendly practices in the production of ceramic resistors, reducing their environmental impact.

VIII. Conclusion

Ceramic resistors play a vital role in various practical applications, from consumer electronics to medical devices. Their unique properties, including high stability, excellent thermal management, and durability, make them indispensable in modern electronic circuits. As technology continues to evolve, the ongoing development of ceramic resistor technology promises to enhance their performance and expand their applications. The future of ceramic resistors in the electronics industry looks bright, with innovations that will further solidify their importance in the ever-changing landscape of technology.

IX. References

1. Academic journals and articles on ceramic resistors and their applications.

2. Industry reports and white papers discussing trends in resistor technology.

3. Manufacturer specifications and product datasheets for various ceramic resistor products.

This comprehensive overview highlights the significance of ceramic resistors in practical applications, showcasing their versatility and importance in the electronics industry.

The Role of Ceramic Resistor Products in Practical Applications

I. Introduction

In the world of electronics, resistors play a crucial role in controlling the flow of electric current. Among the various types of resistors, ceramic resistors have gained significant attention due to their unique properties and versatility. Ceramic resistors are made from a combination of ceramic materials and conductive elements, providing a reliable solution for a wide range of applications. This blog post will explore the role of ceramic resistor products in practical applications, highlighting their types, properties, advantages, challenges, and future trends.

II. Types of Ceramic Resistors

A. Composition and Manufacturing Process

Ceramic resistors are primarily composed of ceramic substrates, which provide electrical insulation and mechanical stability. The conductive materials, often metal oxides or carbon-based compounds, are applied to the ceramic substrate using various production techniques.

1. **Materials Used**: The choice of materials is critical in determining the performance characteristics of ceramic resistors. Common materials include alumina, which offers excellent thermal stability, and various conductive materials that ensure effective current flow.

2. **Production Techniques**: The manufacturing process for ceramic resistors typically involves screen printing and thick film technology. In screen printing, a paste containing conductive materials is applied to the ceramic substrate, followed by a firing process that solidifies the resistor. Thick film technology allows for the creation of resistors with precise resistance values and tolerances.

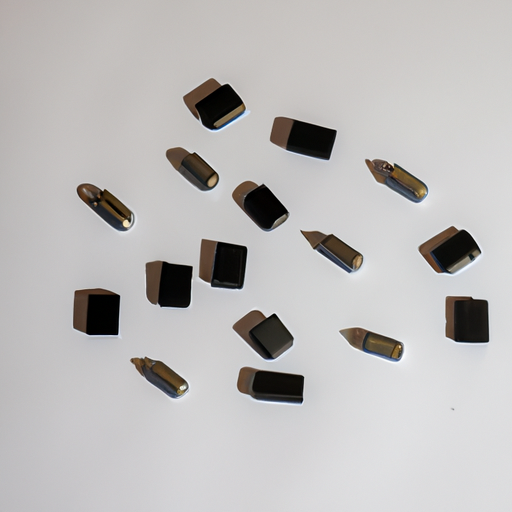

B. Varieties of Ceramic Resistors

Ceramic resistors come in several varieties, each designed for specific applications:

1. **Thick Film Resistors**: These resistors are characterized by their thick conductive layer, making them suitable for high-power applications. They offer good stability and are widely used in consumer electronics.

2. **Thin Film Resistors**: With a thinner conductive layer, thin film resistors provide higher precision and lower noise levels. They are often used in applications requiring high accuracy, such as medical devices and instrumentation.

3. **Power Resistors**: Designed to handle high power levels, power resistors are essential in applications like motor drives and power electronics. Their robust construction allows them to dissipate heat effectively.

4. **Specialty Resistors**: This category includes high-voltage and high-temperature resistors, which are tailored for specific environments and conditions, such as automotive and aerospace applications.

III. Key Properties of Ceramic Resistors

A. Electrical Properties

1. **Resistance Values and Tolerance**: Ceramic resistors are available in a wide range of resistance values, allowing designers to select the appropriate resistor for their specific needs. The tolerance levels can vary, providing flexibility in circuit design.

2. **Temperature Coefficient of Resistance (TCR)**: The TCR indicates how much the resistance changes with temperature. Ceramic resistors typically exhibit low TCR values, ensuring stable performance across varying temperatures.

B. Thermal Properties

1. **Heat Dissipation Capabilities**: One of the standout features of ceramic resistors is their ability to dissipate heat effectively. This property is crucial in preventing overheating and ensuring the longevity of electronic devices.

2. **Thermal Stability**: Ceramic materials are inherently stable at high temperatures, making ceramic resistors suitable for applications in harsh environments.

C. Mechanical Properties

1. **Durability and Reliability**: Ceramic resistors are known for their robustness and resistance to mechanical stress. This durability makes them ideal for use in demanding applications.

2. **Resistance to Environmental Factors**: Ceramic resistors can withstand various environmental conditions, including humidity and extreme temperatures, ensuring reliable performance in diverse settings.

IV. Applications of Ceramic Resistors

A. Consumer Electronics

Ceramic resistors are widely used in consumer electronics, including smartphones, tablets, and computers. They play a vital role in managing power distribution and signal processing, contributing to the overall performance and efficiency of these devices. Additionally, they are found in audio equipment and home appliances, where they help maintain sound quality and energy efficiency.

B. Industrial Applications

In industrial settings, ceramic resistors are essential components in automation and control systems. They are used in power electronics and motor drives, where their ability to handle high power levels and dissipate heat is critical for operational efficiency.

C. Automotive Industry

The automotive industry has increasingly adopted ceramic resistors, particularly in electric vehicles and hybrid systems. These resistors are integral to safety and control systems, ensuring reliable performance in demanding conditions. Their durability and thermal stability make them suitable for use in various automotive applications.

D. Medical Devices

In the medical field, ceramic resistors are crucial for diagnostic and monitoring equipment. Their precision and reliability are essential for accurate measurements. Additionally, they are used in implantable devices, where stability and biocompatibility are paramount.

E. Telecommunications

Ceramic resistors play a significant role in telecommunications, particularly in signal processing and transmission. They are used in networking equipment, where their ability to maintain performance under varying conditions is essential for reliable communication.

V. Advantages of Ceramic Resistors

Ceramic resistors offer several advantages that make them a preferred choice in various applications:

A. High Stability and Reliability

Ceramic resistors are known for their stability over time, ensuring consistent performance in electronic circuits. Their reliability reduces the risk of failure, making them ideal for critical applications.

B. Wide Range of Resistance Values

The availability of ceramic resistors in a broad range of resistance values allows designers to select the most suitable component for their specific needs, enhancing design flexibility.

C. Excellent Thermal Management

The ability of ceramic resistors to dissipate heat effectively contributes to the overall thermal management of electronic devices, preventing overheating and extending their lifespan.

D. Compact Size and Lightweight Design

Ceramic resistors are typically compact and lightweight, making them suitable for modern electronic devices that prioritize space and weight efficiency.

E. Cost-Effectiveness in Mass Production

The manufacturing processes for ceramic resistors allow for cost-effective mass production, making them an economical choice for various applications.

VI. Challenges and Limitations

Despite their many advantages, ceramic resistors also face certain challenges and limitations:

A. Sensitivity to Mechanical Stress

While ceramic resistors are durable, they can be sensitive to mechanical stress, which may lead to cracking or failure in extreme conditions.

B. Limitations in High-Frequency Applications

Ceramic resistors may not perform optimally in high-frequency applications due to parasitic capacitance and inductance, which can affect signal integrity.

C. Potential for Thermal Runaway in Certain Conditions

In specific scenarios, ceramic resistors may experience thermal runaway, where an increase in temperature leads to a further increase in current, potentially causing failure.

VII. Future Trends and Innovations

The field of ceramic resistors is evolving, with several trends and innovations on the horizon:

A. Advances in Materials Science

Research into new materials is paving the way for the development of ceramic resistors with enhanced properties, such as improved thermal stability and lower TCR values.

B. Development of New Manufacturing Techniques

Innovations in manufacturing processes are expected to lead to more efficient production methods, reducing costs and improving the quality of ceramic resistors.

C. Integration with Smart Technologies

As the Internet of Things (IoT) continues to grow, ceramic resistors are likely to be integrated into smart technologies, enabling more efficient and responsive electronic devices.

D. Sustainability and Eco-Friendly Practices

The push for sustainability in manufacturing is leading to the exploration of eco-friendly practices in the production of ceramic resistors, reducing their environmental impact.

VIII. Conclusion

Ceramic resistors play a vital role in various practical applications, from consumer electronics to medical devices. Their unique properties, including high stability, excellent thermal management, and durability, make them indispensable in modern electronic circuits. As technology continues to evolve, the ongoing development of ceramic resistor technology promises to enhance their performance and expand their applications. The future of ceramic resistors in the electronics industry looks bright, with innovations that will further solidify their importance in the ever-changing landscape of technology.

IX. References

1. Academic journals and articles on ceramic resistors and their applications.

2. Industry reports and white papers discussing trends in resistor technology.

3. Manufacturer specifications and product datasheets for various ceramic resistor products.

This comprehensive overview highlights the significance of ceramic resistors in practical applications, showcasing their versatility and importance in the electronics industry.