What are the Product Standards for Variable Resistors?

I. Introduction

Variable resistors, commonly known as potentiometers, rheostats, or trimmers, are essential components in various electronic devices. They allow users to adjust resistance levels, thereby controlling current flow and voltage in circuits. The importance of product standards for variable resistors cannot be overstated, as these standards ensure quality, safety, and interoperability across different applications. This blog post will delve into the types of variable resistors, their applications, the significance of product standards, key standards governing their use, testing and certification processes, challenges in compliance, and future trends in this field.

II. Understanding Variable Resistors

A. Types of Variable Resistors

1. **Potentiometers**: These are three-terminal devices that allow for the adjustment of voltage levels. They are widely used in audio equipment for volume control and in various consumer electronics for tuning and calibration.

2. **Rheostats**: Rheostats are two-terminal variable resistors primarily used to control current. They are often found in applications requiring high power, such as in electric motors and lighting systems.

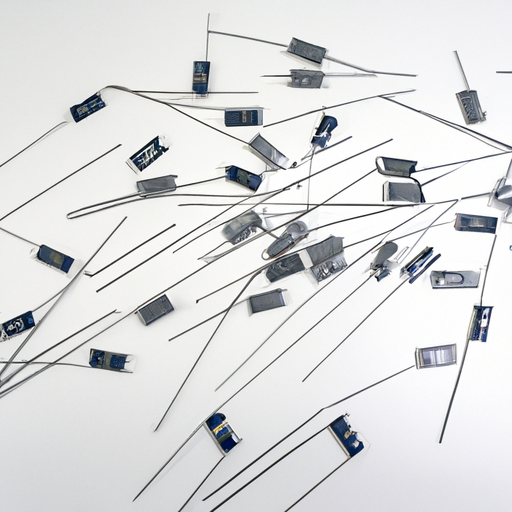

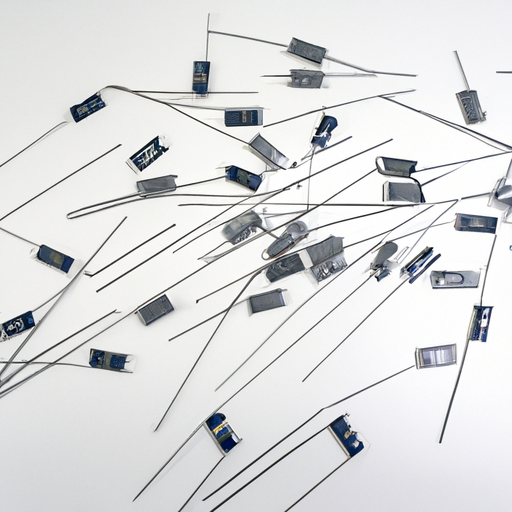

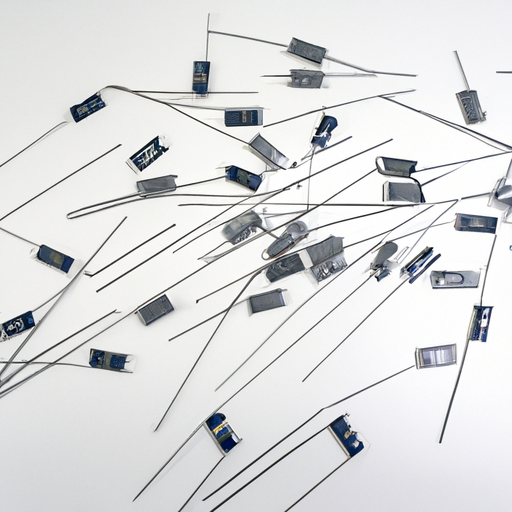

3. **Trimmers**: Trimmers are small potentiometers used for fine-tuning circuits. They are typically adjusted only once during the manufacturing process or for calibration purposes.

B. Applications of Variable Resistors

1. **Audio Equipment**: Variable resistors are crucial in audio devices, allowing users to adjust volume and tone settings. They play a significant role in ensuring sound quality and user experience.

2. **Industrial Controls**: In industrial settings, variable resistors are used in control panels to manage machinery and equipment. They help in adjusting parameters such as speed, temperature, and pressure.

3. **Consumer Electronics**: From televisions to gaming consoles, variable resistors are integral in consumer electronics, enabling users to customize their experience through adjustable settings.

III. Importance of Product Standards

A. Ensuring Quality and Reliability

Product standards for variable resistors help manufacturers maintain consistent quality and reliability in their products. By adhering to established standards, manufacturers can minimize defects and ensure that their products perform as expected.

B. Safety Considerations

Safety is paramount in electrical components. Product standards outline safety requirements that variable resistors must meet to prevent hazards such as electrical shocks, fires, or equipment failures. Compliance with these standards protects both consumers and manufacturers.

C. Facilitating Interoperability

In a global market, interoperability is crucial. Product standards ensure that variable resistors from different manufacturers can work together seamlessly. This is particularly important in complex systems where multiple components must interact.

D. Regulatory Compliance

Many countries have regulations that require compliance with specific product standards. Adhering to these standards not only ensures legal compliance but also enhances a manufacturer's reputation and marketability.

IV. Key Product Standards for Variable Resistors

A. International Electrotechnical Commission (IEC) Standards

1. **IEC 60393 - Variable Resistors**: This standard specifies the requirements for variable resistors, including performance, testing methods, and safety considerations. It serves as a benchmark for manufacturers worldwide.

2. **IEC 61010 - Safety Requirements for Electrical Equipment**: This standard outlines safety requirements for electrical equipment, including variable resistors, ensuring they are safe for use in various applications.

B. American National Standards Institute (ANSI) Standards

1. **ANSI/IEEE Standards for Electrical Components**: These standards provide guidelines for the design, testing, and performance of electrical components, including variable resistors, ensuring they meet industry expectations.

C. European Committee for Electrotechnical Standardization (CENELEC) Standards

CENELEC standards focus on electrical safety and performance within Europe, ensuring that variable resistors meet stringent requirements for use in European markets.

D. Other Relevant Standards

1. **RoHS Compliance**: The Restriction of Hazardous Substances (RoHS) directive limits the use of specific hazardous materials in electrical and electronic equipment, promoting environmental safety.

2. **REACH Regulations**: The Registration, Evaluation, Authorisation, and Restriction of Chemicals (REACH) regulations ensure that chemical substances used in manufacturing are safe for human health and the environment.

V. Testing and Certification Processes

A. Overview of Testing Procedures

1. **Electrical Testing**: This involves assessing the electrical performance of variable resistors, including resistance values, power ratings, and voltage ratings.

2. **Mechanical Testing**: Mechanical tests evaluate the physical durability of variable resistors, including their resistance to wear, temperature fluctuations, and mechanical stress.

3. **Environmental Testing**: Environmental tests assess how variable resistors perform under different environmental conditions, such as humidity, temperature extremes, and exposure to chemicals.

B. Certification Bodies

1. **Underwriters Laboratories (UL)**: UL is a global safety certification organization that tests and certifies electrical components, including variable resistors, ensuring they meet safety standards.

2. **TÜV Rheinland**: This organization provides testing and certification services for various products, including variable resistors, focusing on safety and quality.

3. **Intertek**: Intertek offers testing, inspection, and certification services, helping manufacturers ensure their variable resistors comply with relevant standards.

VI. Challenges in Meeting Product Standards

A. Variability in Manufacturing Processes

Manufacturing processes can vary significantly between different companies and even within the same company. This variability can lead to inconsistencies in product quality and performance, making it challenging to meet established standards.

B. Technological Advancements

As technology evolves, so do the requirements for variable resistors. Manufacturers must continuously adapt to new technologies and standards, which can be resource-intensive and complex.

C. Global Market Considerations

Navigating the global market presents challenges, as different countries may have varying standards and regulations. Manufacturers must ensure compliance with multiple sets of standards, which can complicate production and distribution.

VII. Future Trends in Variable Resistor Standards

A. Impact of Digital Technology

The rise of digital technology is transforming the landscape of variable resistors. Digital potentiometers and programmable resistors are becoming more prevalent, necessitating new standards to address their unique characteristics and applications.

B. Sustainability and Environmental Standards

As environmental concerns grow, there is an increasing emphasis on sustainability in manufacturing. Future standards for variable resistors are likely to focus on reducing environmental impact, promoting the use of eco-friendly materials, and ensuring recyclability.

C. Evolving Safety Regulations

Safety regulations are continually evolving to address new risks associated with electrical components. Manufacturers must stay informed about these changes and adapt their products accordingly to ensure compliance.

VIII. Conclusion

In conclusion, product standards for variable resistors play a crucial role in ensuring quality, safety, and interoperability in various applications. As technology advances and the market evolves, manufacturers and consumers must remain vigilant in understanding and adhering to these standards. By doing so, they can contribute to a safer, more reliable, and sustainable future for variable resistors and the electronic devices that rely on them.

IX. References

A comprehensive list of standards, guidelines, and relevant literature can be found through organizations such as the International Electrotechnical Commission (IEC), American National Standards Institute (ANSI), and European Committee for Electrotechnical Standardization (CENELEC). Additionally, industry resources and organizations provide valuable insights into the latest developments in variable resistor standards and compliance.

What are the Product Standards for Variable Resistors?

I. Introduction

Variable resistors, commonly known as potentiometers, rheostats, or trimmers, are essential components in various electronic devices. They allow users to adjust resistance levels, thereby controlling current flow and voltage in circuits. The importance of product standards for variable resistors cannot be overstated, as these standards ensure quality, safety, and interoperability across different applications. This blog post will delve into the types of variable resistors, their applications, the significance of product standards, key standards governing their use, testing and certification processes, challenges in compliance, and future trends in this field.

II. Understanding Variable Resistors

A. Types of Variable Resistors

1. **Potentiometers**: These are three-terminal devices that allow for the adjustment of voltage levels. They are widely used in audio equipment for volume control and in various consumer electronics for tuning and calibration.

2. **Rheostats**: Rheostats are two-terminal variable resistors primarily used to control current. They are often found in applications requiring high power, such as in electric motors and lighting systems.

3. **Trimmers**: Trimmers are small potentiometers used for fine-tuning circuits. They are typically adjusted only once during the manufacturing process or for calibration purposes.

B. Applications of Variable Resistors

1. **Audio Equipment**: Variable resistors are crucial in audio devices, allowing users to adjust volume and tone settings. They play a significant role in ensuring sound quality and user experience.

2. **Industrial Controls**: In industrial settings, variable resistors are used in control panels to manage machinery and equipment. They help in adjusting parameters such as speed, temperature, and pressure.

3. **Consumer Electronics**: From televisions to gaming consoles, variable resistors are integral in consumer electronics, enabling users to customize their experience through adjustable settings.

III. Importance of Product Standards

A. Ensuring Quality and Reliability

Product standards for variable resistors help manufacturers maintain consistent quality and reliability in their products. By adhering to established standards, manufacturers can minimize defects and ensure that their products perform as expected.

B. Safety Considerations

Safety is paramount in electrical components. Product standards outline safety requirements that variable resistors must meet to prevent hazards such as electrical shocks, fires, or equipment failures. Compliance with these standards protects both consumers and manufacturers.

C. Facilitating Interoperability

In a global market, interoperability is crucial. Product standards ensure that variable resistors from different manufacturers can work together seamlessly. This is particularly important in complex systems where multiple components must interact.

D. Regulatory Compliance

Many countries have regulations that require compliance with specific product standards. Adhering to these standards not only ensures legal compliance but also enhances a manufacturer's reputation and marketability.

IV. Key Product Standards for Variable Resistors

A. International Electrotechnical Commission (IEC) Standards

1. **IEC 60393 - Variable Resistors**: This standard specifies the requirements for variable resistors, including performance, testing methods, and safety considerations. It serves as a benchmark for manufacturers worldwide.

2. **IEC 61010 - Safety Requirements for Electrical Equipment**: This standard outlines safety requirements for electrical equipment, including variable resistors, ensuring they are safe for use in various applications.

B. American National Standards Institute (ANSI) Standards

1. **ANSI/IEEE Standards for Electrical Components**: These standards provide guidelines for the design, testing, and performance of electrical components, including variable resistors, ensuring they meet industry expectations.

C. European Committee for Electrotechnical Standardization (CENELEC) Standards

CENELEC standards focus on electrical safety and performance within Europe, ensuring that variable resistors meet stringent requirements for use in European markets.

D. Other Relevant Standards

1. **RoHS Compliance**: The Restriction of Hazardous Substances (RoHS) directive limits the use of specific hazardous materials in electrical and electronic equipment, promoting environmental safety.

2. **REACH Regulations**: The Registration, Evaluation, Authorisation, and Restriction of Chemicals (REACH) regulations ensure that chemical substances used in manufacturing are safe for human health and the environment.

V. Testing and Certification Processes

A. Overview of Testing Procedures

1. **Electrical Testing**: This involves assessing the electrical performance of variable resistors, including resistance values, power ratings, and voltage ratings.

2. **Mechanical Testing**: Mechanical tests evaluate the physical durability of variable resistors, including their resistance to wear, temperature fluctuations, and mechanical stress.

3. **Environmental Testing**: Environmental tests assess how variable resistors perform under different environmental conditions, such as humidity, temperature extremes, and exposure to chemicals.

B. Certification Bodies

1. **Underwriters Laboratories (UL)**: UL is a global safety certification organization that tests and certifies electrical components, including variable resistors, ensuring they meet safety standards.

2. **TÜV Rheinland**: This organization provides testing and certification services for various products, including variable resistors, focusing on safety and quality.

3. **Intertek**: Intertek offers testing, inspection, and certification services, helping manufacturers ensure their variable resistors comply with relevant standards.

VI. Challenges in Meeting Product Standards

A. Variability in Manufacturing Processes

Manufacturing processes can vary significantly between different companies and even within the same company. This variability can lead to inconsistencies in product quality and performance, making it challenging to meet established standards.

B. Technological Advancements

As technology evolves, so do the requirements for variable resistors. Manufacturers must continuously adapt to new technologies and standards, which can be resource-intensive and complex.

C. Global Market Considerations

Navigating the global market presents challenges, as different countries may have varying standards and regulations. Manufacturers must ensure compliance with multiple sets of standards, which can complicate production and distribution.

VII. Future Trends in Variable Resistor Standards

A. Impact of Digital Technology

The rise of digital technology is transforming the landscape of variable resistors. Digital potentiometers and programmable resistors are becoming more prevalent, necessitating new standards to address their unique characteristics and applications.

B. Sustainability and Environmental Standards

As environmental concerns grow, there is an increasing emphasis on sustainability in manufacturing. Future standards for variable resistors are likely to focus on reducing environmental impact, promoting the use of eco-friendly materials, and ensuring recyclability.

C. Evolving Safety Regulations

Safety regulations are continually evolving to address new risks associated with electrical components. Manufacturers must stay informed about these changes and adapt their products accordingly to ensure compliance.

VIII. Conclusion

In conclusion, product standards for variable resistors play a crucial role in ensuring quality, safety, and interoperability in various applications. As technology advances and the market evolves, manufacturers and consumers must remain vigilant in understanding and adhering to these standards. By doing so, they can contribute to a safer, more reliable, and sustainable future for variable resistors and the electronic devices that rely on them.

IX. References

A comprehensive list of standards, guidelines, and relevant literature can be found through organizations such as the International Electrotechnical Commission (IEC), American National Standards Institute (ANSI), and European Committee for Electrotechnical Standardization (CENELEC). Additionally, industry resources and organizations provide valuable insights into the latest developments in variable resistor standards and compliance.