Popular Porcelain Tube Resistor Product Models

I. Introduction

In the world of electronics, resistors play a crucial role in controlling the flow of electric current. Among the various types of resistors, porcelain tube resistors stand out due to their unique construction and performance characteristics. These resistors are designed to handle high voltages and power levels, making them essential components in many industrial and commercial applications. This article aims to provide an in-depth look at porcelain tube resistors, their key features, popular product models, and guidance on selecting the right resistor for specific needs.

II. Understanding Porcelain Tube Resistors

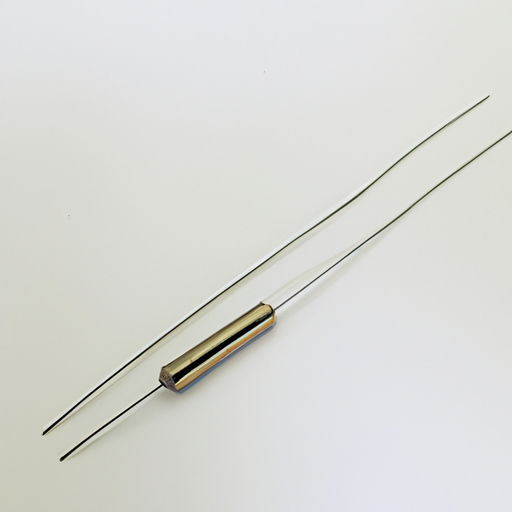

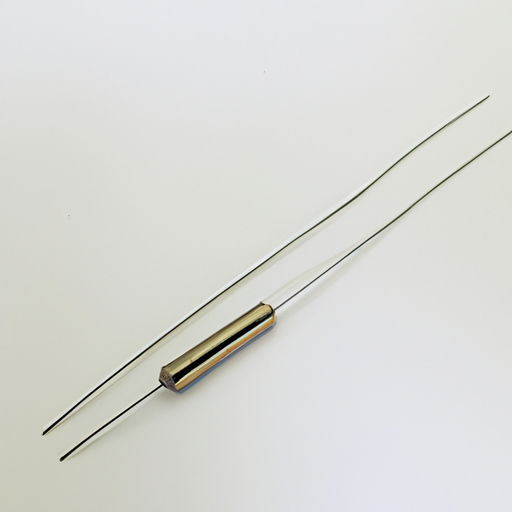

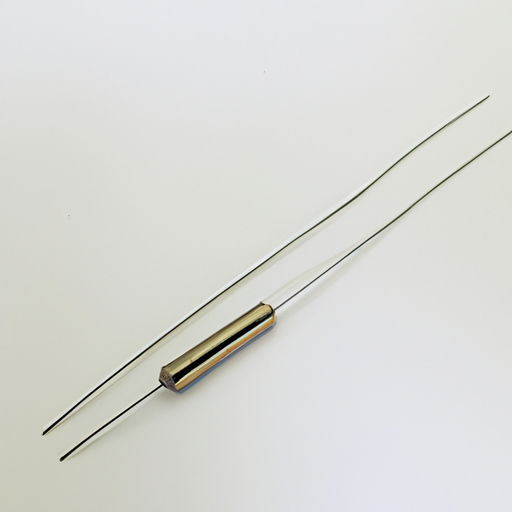

A. Composition and Construction

Porcelain tube resistors are made from a combination of high-quality ceramic materials and resistive elements. The ceramic casing provides excellent thermal stability and electrical insulation, while the resistive element is typically composed of a metal oxide or carbon-based material. This combination allows porcelain tube resistors to withstand high temperatures and voltages without degrading.

1. Materials Used in Porcelain Tube Resistors

The primary material used in the construction of porcelain tube resistors is porcelain, a type of ceramic that is known for its durability and insulating properties. The resistive element can vary, with options including carbon, metal film, or wire-wound materials, each offering different resistance values and performance characteristics.

2. Design Features and Benefits

Porcelain tube resistors are designed to be robust and reliable. Their tubular shape allows for efficient heat dissipation, which is critical in high-power applications. Additionally, the porcelain casing protects the resistive element from environmental factors such as moisture, dust, and mechanical stress, enhancing the resistor's longevity.

B. Functionality and Applications

Porcelain tube resistors serve a vital role in electrical circuits by limiting current flow and dividing voltages. They are commonly used in power supplies, amplifiers, and various industrial equipment.

1. Role in Electrical Circuits

In electronic circuits, resistors are essential for controlling current and voltage levels. Porcelain tube resistors, with their high power ratings, are particularly suited for applications where standard resistors may fail due to overheating or voltage spikes.

2. Common Applications in Various Industries

These resistors find applications in a wide range of industries, including telecommunications, automotive, aerospace, and power generation. They are often used in high-voltage power supplies, motor control circuits, and as load resistors in testing equipment.

III. Key Features of Porcelain Tube Resistors

A. Thermal Stability

One of the standout features of porcelain tube resistors is their thermal stability. They can operate effectively at high temperatures without significant changes in resistance, making them ideal for demanding applications.

B. High Voltage and Power Ratings

Porcelain tube resistors are designed to handle high voltage and power levels, often exceeding those of standard resistors. This capability allows them to be used in applications where other resistors would fail.

C. Resistance to Environmental Factors

The porcelain casing provides excellent protection against environmental factors such as moisture, dust, and chemicals. This resistance ensures that the resistor maintains its performance over time, even in harsh conditions.

D. Longevity and Reliability

Due to their robust construction and materials, porcelain tube resistors are known for their longevity and reliability. They can operate for extended periods without degradation, making them a cost-effective choice for many applications.

IV. Popular Porcelain Tube Resistor Models

A. Overview of Leading Manufacturers

Several manufacturers are known for producing high-quality porcelain tube resistors. Here, we will examine three leading companies in the industry.

1. Manufacturer A: Vishay

Vishay is a well-respected name in the electronics industry, known for its wide range of resistors, including porcelain tube models. Their products are recognized for their precision and reliability.

2. Manufacturer B: Ohmite

Ohmite specializes in high-power resistors and offers a variety of porcelain tube resistors designed for demanding applications. Their products are known for their durability and performance.

3. Manufacturer C: TE Connectivity

TE Connectivity produces a range of electronic components, including porcelain tube resistors. Their focus on innovation and quality makes them a popular choice among engineers.

B. Detailed Examination of Popular Models

1. Model 1: Vishay PSM Series

Specifications: Resistance range from 1Ω to 1MΩ, power rating up to 100W.

Features: High thermal stability, low temperature coefficient.

Applications: Suitable for power supplies and industrial equipment.

2. Model 2: Ohmite 50 Series

Specifications: Resistance range from 0.1Ω to 10MΩ, power rating up to 200W.

Features: Excellent heat dissipation, robust construction.

Applications: Ideal for motor control and high-power applications.

3. Model 3: TE Connectivity RST Series

Specifications: Resistance range from 10Ω to 1MΩ, power rating up to 150W.

Features: High voltage capability, moisture-resistant design.

Applications: Used in telecommunications and aerospace applications.

4. Model 4: Vishay PSM-100

Specifications: Resistance range from 1Ω to 100kΩ, power rating of 100W.

Features: Low noise, high reliability.

Applications: Suitable for audio equipment and precision circuits.

5. Model 5: Ohmite 100 Series

Specifications: Resistance range from 0.5Ω to 5MΩ, power rating up to 300W.

Features: High power handling, excellent thermal performance.

Applications: Commonly used in power electronics and testing equipment.

V. Comparison of Popular Models

A. Performance Metrics

When comparing porcelain tube resistors, several performance metrics are essential to consider:

1. Resistance Range

Different models offer varying resistance ranges, allowing engineers to select the appropriate resistor for their specific application.

2. Power Rating

Power rating is a critical factor, especially in high-power applications. Models like the Ohmite 100 Series excel in this area, providing up to 300W.

3. Temperature Coefficient

The temperature coefficient indicates how much the resistance changes with temperature. Lower coefficients are preferable for precision applications.

B. Cost Analysis

Cost can vary significantly between models and manufacturers. While high-performance models may come at a premium, they often provide better reliability and longevity, making them a worthwhile investment.

C. User Reviews and Feedback

User reviews can provide valuable insights into the performance and reliability of specific models. Many users praise the durability and thermal stability of porcelain tube resistors, particularly in demanding environments.

VI. Choosing the Right Porcelain Tube Resistor

A. Factors to Consider

When selecting a porcelain tube resistor, several factors should be taken into account:

1. Application Requirements

Understanding the specific requirements of your application, including voltage, current, and resistance needs, is crucial for selecting the right resistor.

2. Environmental Conditions

Consider the environmental conditions in which the resistor will operate. If the resistor will be exposed to moisture or extreme temperatures, choose a model with appropriate protective features.

3. Budget Constraints

While it’s essential to find a resistor that meets performance requirements, budget constraints may also play a role in your decision. Balance cost with the expected longevity and reliability of the resistor.

B. Recommendations for Specific Applications

For high-power applications, models like the Ohmite 100 Series are recommended due to their high power ratings and durability. For precision applications, the Vishay PSM Series offers excellent thermal stability and low noise.

VII. Conclusion

Porcelain tube resistors are vital components in many electronic circuits, offering high voltage and power ratings, thermal stability, and resistance to environmental factors. With various models available from leading manufacturers, engineers can find the right resistor to meet their specific needs. By considering factors such as application requirements, environmental conditions, and budget constraints, you can make an informed decision when selecting a porcelain tube resistor.

VIII. References

- Vishay Product Catalog

- Ohmite Resistor Specifications

- TE Connectivity Resistor Information

- User Reviews and Feedback on Electronic Components

This comprehensive overview of porcelain tube resistors and their popular models aims to equip readers with the knowledge needed to make informed decisions in their electronic design and application processes.

Popular Porcelain Tube Resistor Product Models

I. Introduction

In the world of electronics, resistors play a crucial role in controlling the flow of electric current. Among the various types of resistors, porcelain tube resistors stand out due to their unique construction and performance characteristics. These resistors are designed to handle high voltages and power levels, making them essential components in many industrial and commercial applications. This article aims to provide an in-depth look at porcelain tube resistors, their key features, popular product models, and guidance on selecting the right resistor for specific needs.

II. Understanding Porcelain Tube Resistors

A. Composition and Construction

Porcelain tube resistors are made from a combination of high-quality ceramic materials and resistive elements. The ceramic casing provides excellent thermal stability and electrical insulation, while the resistive element is typically composed of a metal oxide or carbon-based material. This combination allows porcelain tube resistors to withstand high temperatures and voltages without degrading.

1. Materials Used in Porcelain Tube Resistors

The primary material used in the construction of porcelain tube resistors is porcelain, a type of ceramic that is known for its durability and insulating properties. The resistive element can vary, with options including carbon, metal film, or wire-wound materials, each offering different resistance values and performance characteristics.

2. Design Features and Benefits

Porcelain tube resistors are designed to be robust and reliable. Their tubular shape allows for efficient heat dissipation, which is critical in high-power applications. Additionally, the porcelain casing protects the resistive element from environmental factors such as moisture, dust, and mechanical stress, enhancing the resistor's longevity.

B. Functionality and Applications

Porcelain tube resistors serve a vital role in electrical circuits by limiting current flow and dividing voltages. They are commonly used in power supplies, amplifiers, and various industrial equipment.

1. Role in Electrical Circuits

In electronic circuits, resistors are essential for controlling current and voltage levels. Porcelain tube resistors, with their high power ratings, are particularly suited for applications where standard resistors may fail due to overheating or voltage spikes.

2. Common Applications in Various Industries

These resistors find applications in a wide range of industries, including telecommunications, automotive, aerospace, and power generation. They are often used in high-voltage power supplies, motor control circuits, and as load resistors in testing equipment.

III. Key Features of Porcelain Tube Resistors

A. Thermal Stability

One of the standout features of porcelain tube resistors is their thermal stability. They can operate effectively at high temperatures without significant changes in resistance, making them ideal for demanding applications.

B. High Voltage and Power Ratings

Porcelain tube resistors are designed to handle high voltage and power levels, often exceeding those of standard resistors. This capability allows them to be used in applications where other resistors would fail.

C. Resistance to Environmental Factors

The porcelain casing provides excellent protection against environmental factors such as moisture, dust, and chemicals. This resistance ensures that the resistor maintains its performance over time, even in harsh conditions.

D. Longevity and Reliability

Due to their robust construction and materials, porcelain tube resistors are known for their longevity and reliability. They can operate for extended periods without degradation, making them a cost-effective choice for many applications.

IV. Popular Porcelain Tube Resistor Models

A. Overview of Leading Manufacturers

Several manufacturers are known for producing high-quality porcelain tube resistors. Here, we will examine three leading companies in the industry.

1. Manufacturer A: Vishay

Vishay is a well-respected name in the electronics industry, known for its wide range of resistors, including porcelain tube models. Their products are recognized for their precision and reliability.

2. Manufacturer B: Ohmite

Ohmite specializes in high-power resistors and offers a variety of porcelain tube resistors designed for demanding applications. Their products are known for their durability and performance.

3. Manufacturer C: TE Connectivity

TE Connectivity produces a range of electronic components, including porcelain tube resistors. Their focus on innovation and quality makes them a popular choice among engineers.

B. Detailed Examination of Popular Models

1. Model 1: Vishay PSM Series

Specifications: Resistance range from 1Ω to 1MΩ, power rating up to 100W.

Features: High thermal stability, low temperature coefficient.

Applications: Suitable for power supplies and industrial equipment.

2. Model 2: Ohmite 50 Series

Specifications: Resistance range from 0.1Ω to 10MΩ, power rating up to 200W.

Features: Excellent heat dissipation, robust construction.

Applications: Ideal for motor control and high-power applications.

3. Model 3: TE Connectivity RST Series

Specifications: Resistance range from 10Ω to 1MΩ, power rating up to 150W.

Features: High voltage capability, moisture-resistant design.

Applications: Used in telecommunications and aerospace applications.

4. Model 4: Vishay PSM-100

Specifications: Resistance range from 1Ω to 100kΩ, power rating of 100W.

Features: Low noise, high reliability.

Applications: Suitable for audio equipment and precision circuits.

5. Model 5: Ohmite 100 Series

Specifications: Resistance range from 0.5Ω to 5MΩ, power rating up to 300W.

Features: High power handling, excellent thermal performance.

Applications: Commonly used in power electronics and testing equipment.

V. Comparison of Popular Models

A. Performance Metrics

When comparing porcelain tube resistors, several performance metrics are essential to consider:

1. Resistance Range

Different models offer varying resistance ranges, allowing engineers to select the appropriate resistor for their specific application.

2. Power Rating

Power rating is a critical factor, especially in high-power applications. Models like the Ohmite 100 Series excel in this area, providing up to 300W.

3. Temperature Coefficient

The temperature coefficient indicates how much the resistance changes with temperature. Lower coefficients are preferable for precision applications.

B. Cost Analysis

Cost can vary significantly between models and manufacturers. While high-performance models may come at a premium, they often provide better reliability and longevity, making them a worthwhile investment.

C. User Reviews and Feedback

User reviews can provide valuable insights into the performance and reliability of specific models. Many users praise the durability and thermal stability of porcelain tube resistors, particularly in demanding environments.

VI. Choosing the Right Porcelain Tube Resistor

A. Factors to Consider

When selecting a porcelain tube resistor, several factors should be taken into account:

1. Application Requirements

Understanding the specific requirements of your application, including voltage, current, and resistance needs, is crucial for selecting the right resistor.

2. Environmental Conditions

Consider the environmental conditions in which the resistor will operate. If the resistor will be exposed to moisture or extreme temperatures, choose a model with appropriate protective features.

3. Budget Constraints

While it’s essential to find a resistor that meets performance requirements, budget constraints may also play a role in your decision. Balance cost with the expected longevity and reliability of the resistor.

B. Recommendations for Specific Applications

For high-power applications, models like the Ohmite 100 Series are recommended due to their high power ratings and durability. For precision applications, the Vishay PSM Series offers excellent thermal stability and low noise.

VII. Conclusion

Porcelain tube resistors are vital components in many electronic circuits, offering high voltage and power ratings, thermal stability, and resistance to environmental factors. With various models available from leading manufacturers, engineers can find the right resistor to meet their specific needs. By considering factors such as application requirements, environmental conditions, and budget constraints, you can make an informed decision when selecting a porcelain tube resistor.

VIII. References

- Vishay Product Catalog

- Ohmite Resistor Specifications

- TE Connectivity Resistor Information

- User Reviews and Feedback on Electronic Components

This comprehensive overview of porcelain tube resistors and their popular models aims to equip readers with the knowledge needed to make informed decisions in their electronic design and application processes.