LED drivers are an essential component in LED lighting systems, providing the necessary power and control to ensure optimal performance and efficiency. As technology continues to advance, the manufacturing processes for LED drivers have also evolved to meet the growing demands for energy-efficient lighting solutions. In this article, we will explore the latest LED driver manufacturing processes and how they are shaping the future of LED lighting.

One of the key trends in LED driver manufacturing is the shift towards more efficient and compact designs. With the increasing demand for smaller and more versatile LED lighting solutions, manufacturers are focusing on developing drivers that are not only more energy-efficient but also more space-saving. This has led to the development of advanced manufacturing processes that allow for the integration of more components into a smaller form factor, resulting in LED drivers that are more efficient and easier to install.

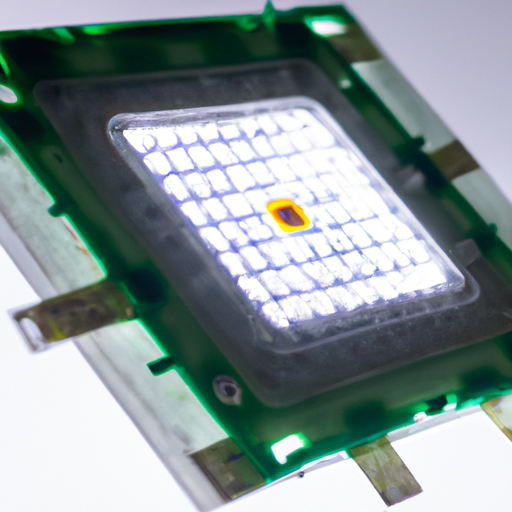

One of the latest manufacturing processes being used in LED driver production is surface mount technology (SMT). SMT allows for the placement of components directly onto the surface of the printed circuit board (PCB), eliminating the need for through-hole components and reducing the overall size of the driver. This results in LED drivers that are more compact, lightweight, and cost-effective, making them ideal for a wide range of applications.

Another key trend in LED driver manufacturing is the use of advanced materials and components. Manufacturers are increasingly turning to high-quality materials such as ceramic substrates and advanced semiconductors to improve the performance and reliability of LED drivers. These materials offer better thermal conductivity, higher power handling capabilities, and improved resistance to environmental factors, making them ideal for use in demanding lighting applications.

In addition to advanced materials, manufacturers are also incorporating innovative features into LED drivers to enhance their functionality and performance. For example, some LED drivers now come equipped with dimming capabilities, allowing users to adjust the brightness of the light output to suit their preferences. This not only improves the user experience but also helps to save energy and extend the lifespan of the LED lighting system.

Furthermore, manufacturers are also focusing on improving the efficiency of LED drivers through the use of advanced control algorithms and power management techniques. By optimizing the power delivery and control mechanisms, manufacturers are able to maximize the efficiency of LED drivers, reducing energy consumption and minimizing heat generation. This not only helps to improve the overall performance of LED lighting systems but also extends the lifespan of the LEDs themselves.

Overall, the latest LED driver manufacturing processes are focused on improving efficiency, reliability, and performance to meet the growing demands for energy-efficient lighting solutions. By incorporating advanced materials, innovative features, and efficient control algorithms, manufacturers are able to produce LED drivers that are smaller, more efficient, and more reliable than ever before. As technology continues to advance, we can expect to see even more advancements in LED driver manufacturing processes, further driving the adoption of LED lighting as the preferred choice for energy-efficient illumination.

LED drivers are an essential component in LED lighting systems, providing the necessary power and control to ensure optimal performance and efficiency. As technology continues to advance, the manufacturing processes for LED drivers have also evolved to meet the growing demands for energy-efficient lighting solutions. In this article, we will explore the latest LED driver manufacturing processes and how they are shaping the future of LED lighting.

One of the key trends in LED driver manufacturing is the shift towards more efficient and compact designs. With the increasing demand for smaller and more versatile LED lighting solutions, manufacturers are focusing on developing drivers that are not only more energy-efficient but also more space-saving. This has led to the development of advanced manufacturing processes that allow for the integration of more components into a smaller form factor, resulting in LED drivers that are more efficient and easier to install.

One of the latest manufacturing processes being used in LED driver production is surface mount technology (SMT). SMT allows for the placement of components directly onto the surface of the printed circuit board (PCB), eliminating the need for through-hole components and reducing the overall size of the driver. This results in LED drivers that are more compact, lightweight, and cost-effective, making them ideal for a wide range of applications.

Another key trend in LED driver manufacturing is the use of advanced materials and components. Manufacturers are increasingly turning to high-quality materials such as ceramic substrates and advanced semiconductors to improve the performance and reliability of LED drivers. These materials offer better thermal conductivity, higher power handling capabilities, and improved resistance to environmental factors, making them ideal for use in demanding lighting applications.

In addition to advanced materials, manufacturers are also incorporating innovative features into LED drivers to enhance their functionality and performance. For example, some LED drivers now come equipped with dimming capabilities, allowing users to adjust the brightness of the light output to suit their preferences. This not only improves the user experience but also helps to save energy and extend the lifespan of the LED lighting system.

Furthermore, manufacturers are also focusing on improving the efficiency of LED drivers through the use of advanced control algorithms and power management techniques. By optimizing the power delivery and control mechanisms, manufacturers are able to maximize the efficiency of LED drivers, reducing energy consumption and minimizing heat generation. This not only helps to improve the overall performance of LED lighting systems but also extends the lifespan of the LEDs themselves.

Overall, the latest LED driver manufacturing processes are focused on improving efficiency, reliability, and performance to meet the growing demands for energy-efficient lighting solutions. By incorporating advanced materials, innovative features, and efficient control algorithms, manufacturers are able to produce LED drivers that are smaller, more efficient, and more reliable than ever before. As technology continues to advance, we can expect to see even more advancements in LED driver manufacturing processes, further driving the adoption of LED lighting as the preferred choice for energy-efficient illumination.