The mainstream VCO (Voltage Controlled Oscillator) production process is a key electronic component manufacturing technology that plays a vital role in wireless communications, radio frequency circuits, radar systems, etc. VCO is a circuit that can change the output frequency according to the change of input voltage, and is usually used in frequency synthesizers, frequency modulation, frequency tuning and other applications.

The production process of VCO involves multiple steps and process flows, including material preparation, device design, process preparation, test verification, etc. The following will introduce the production process flow of mainstream

VCO voltage-controlled oscillators in detail.

1. Material preparation The manufacture of VCO requires the use of a series of high-purity semiconductor materials, such as silicon, gallium nitride, aluminum nitride, etc. These materials need to be strictly screened and tested to ensure that their quality meets the requirements. At the same time, various auxiliary materials such as metal materials, insulating materials, conductive materials, etc. need to be prepared to support the manufacture of VCO devices.

2. Device Design VCO design is a key step in the VCO production process. It needs to determine the structure, parameters and circuit topology of the VCO according to specific application requirements and performance indicators. Designers need to consider factors such as the VCO's frequency range, frequency stability, phase noise, power consumption, etc. to ensure that the VCO can meet the requirements of actual applications.

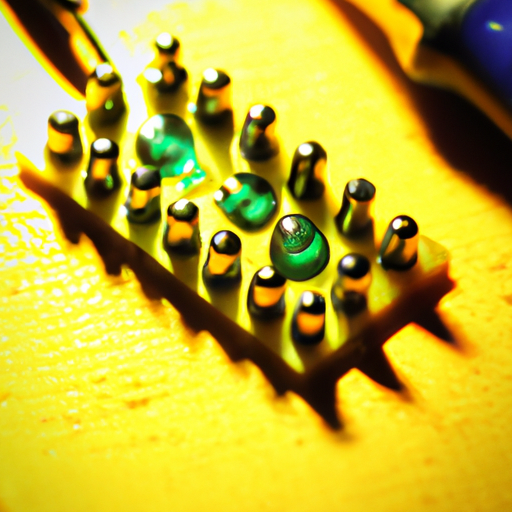

3. Process preparation The process preparation of VCO includes multiple steps, such as wafer preparation, photolithography, evaporation, ion implantation, metallization, packaging, etc. In the wafer preparation stage, gallium nitride or other semiconductor materials need to be grown on silicon wafers through chemical vapor deposition (CVD) or physical vapor deposition (PVD) and other technologies. In the photolithography and evaporation stages, photolithography machines and evaporators are needed to pattern and metallize the wafers. In the ion implantation stage, the wafers need to be doped by ion implanters. Finally, in the packaging stage, the wafers need to be packaged in a metal casing and connected to external pins.

4. Test and Verification After the VCO production process is completed, strict test and verification are required to ensure that the performance of the VCO meets the design requirements. Test and verification include frequency test, phase noise test, power consumption test, temperature stability test, etc. Only after passing the test and verification can the VCO be considered a qualified product and can be put into market application.

In general, the production process of mainstream VCO voltage-controlled oscillators is a complex and sophisticated technology that requires coordination and strict control of multiple links. Only by striving for excellence in material preparation, device design, process preparation, and test verification can we produce VCO products with stable performance and reliable quality, providing reliable support for fields such as wireless communications and RF circuits.

The mainstream VCO (Voltage Controlled Oscillator) production process is a key electronic component manufacturing technology that plays a vital role in wireless communications, radio frequency circuits, radar systems, etc. VCO is a circuit that can change the output frequency according to the change of input voltage, and is usually used in frequency synthesizers, frequency modulation, frequency tuning and other applications.

The production process of VCO involves multiple steps and process flows, including material preparation, device design, process preparation, test verification, etc. The following will introduce the production process flow of mainstream

VCO voltage-controlled oscillators in detail.

1. Material preparation The manufacture of VCO requires the use of a series of high-purity semiconductor materials, such as silicon, gallium nitride, aluminum nitride, etc. These materials need to be strictly screened and tested to ensure that their quality meets the requirements. At the same time, various auxiliary materials such as metal materials, insulating materials, conductive materials, etc. need to be prepared to support the manufacture of VCO devices.

2. Device Design VCO design is a key step in the VCO production process. It needs to determine the structure, parameters and circuit topology of the VCO according to specific application requirements and performance indicators. Designers need to consider factors such as the VCO's frequency range, frequency stability, phase noise, power consumption, etc. to ensure that the VCO can meet the requirements of actual applications.

3. Process preparation The process preparation of VCO includes multiple steps, such as wafer preparation, photolithography, evaporation, ion implantation, metallization, packaging, etc. In the wafer preparation stage, gallium nitride or other semiconductor materials need to be grown on silicon wafers through chemical vapor deposition (CVD) or physical vapor deposition (PVD) and other technologies. In the photolithography and evaporation stages, photolithography machines and evaporators are needed to pattern and metallize the wafers. In the ion implantation stage, the wafers need to be doped by ion implanters. Finally, in the packaging stage, the wafers need to be packaged in a metal casing and connected to external pins.

4. Test and Verification After the VCO production process is completed, strict test and verification are required to ensure that the performance of the VCO meets the design requirements. Test and verification include frequency test, phase noise test, power consumption test, temperature stability test, etc. Only after passing the test and verification can the VCO be considered a qualified product and can be put into market application.

In general, the production process of mainstream VCO voltage-controlled oscillators is a complex and sophisticated technology that requires coordination and strict control of multiple links. Only by striving for excellence in material preparation, device design, process preparation, and test verification can we produce VCO products with stable performance and reliable quality, providing reliable support for fields such as wireless communications and RF circuits.