A digital-to-analog converter (DAC) is an electronic device that converts digital signals into analog signals. It plays a vital role in various applications, such as audio equipment, communication systems, instrumentation, etc. The performance of the DAC directly affects the performance of the entire system, so a series of strict processes need to be adopted during the production process to ensure its quality and stability.

The production process of DAC usually includes the following steps:

1. Design stage: In the design stage, engineers need to design a DAC circuit that meets the requirements according to the product requirements and specifications. This includes selecting the appropriate circuit structure, device parameters, circuit layout, etc. The quality of the design stage directly affects the success of the subsequent production process.

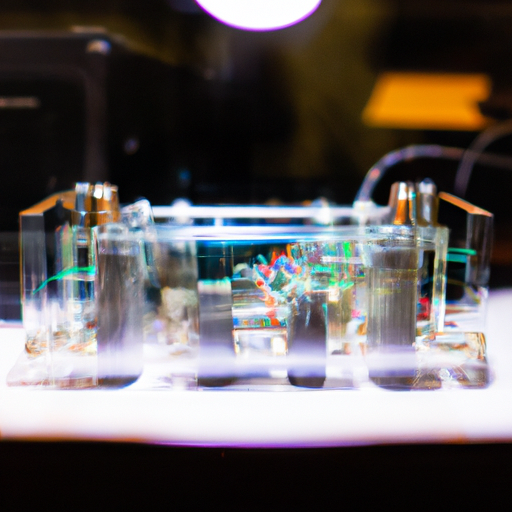

2. Manufacturing process: The manufacturing process is the key link in DAC production. The first is chip manufacturing, including wafer processing, photolithography, thin film deposition, ion implantation and other processes. These processes require high-precision equipment and technical support to ensure the quality and stability of the chip. Next is the packaging process, which encapsulates the chip in a plastic or metal package to protect the chip and facilitate the connection to the external circuit.

3. Testing and calibration: After production, the DAC needs to be rigorously tested and calibrated to ensure that its performance meets the specifications. The test includes static test and dynamic test. The static test mainly detects the basic parameters of the DAC such as resolution and accuracy, while the dynamic test detects the performance of the DAC under different working conditions. Calibration is to adjust the DAC according to the test results to improve its performance and stability.

4. Quality control: Quality control is a crucial link in the entire production process. Through strict quality control measures, the quality and stability of DAC can be ensured. Quality control includes raw material testing, production process monitoring, finished product testing, etc. to ensure that each DAC meets the specification requirements.

In general, the production process of DAC is a complex and rigorous process that requires the support of various technologies and equipment. Only through strict process control and quality management can high-quality and stable DAC products be produced to meet the needs of various applications. In the future, with the continuous development of technology, the production process of DAC will continue to improve to meet the market demand for high-performance and high-stability DAC products.

A digital-to-analog converter (DAC) is an electronic device that converts digital signals into analog signals. It plays a vital role in various applications, such as audio equipment, communication systems, instrumentation, etc. The performance of the DAC directly affects the performance of the entire system, so a series of strict processes need to be adopted during the production process to ensure its quality and stability.

The production process of DAC usually includes the following steps:

1. Design stage: In the design stage, engineers need to design a DAC circuit that meets the requirements according to the product requirements and specifications. This includes selecting the appropriate circuit structure, device parameters, circuit layout, etc. The quality of the design stage directly affects the success of the subsequent production process.

2. Manufacturing process: The manufacturing process is the key link in DAC production. The first is chip manufacturing, including wafer processing, photolithography, thin film deposition, ion implantation and other processes. These processes require high-precision equipment and technical support to ensure the quality and stability of the chip. Next is the packaging process, which encapsulates the chip in a plastic or metal package to protect the chip and facilitate the connection to the external circuit.

3. Testing and calibration: After production, the DAC needs to be rigorously tested and calibrated to ensure that its performance meets the specifications. The test includes static test and dynamic test. The static test mainly detects the basic parameters of the DAC such as resolution and accuracy, while the dynamic test detects the performance of the DAC under different working conditions. Calibration is to adjust the DAC according to the test results to improve its performance and stability.

4. Quality control: Quality control is a crucial link in the entire production process. Through strict quality control measures, the quality and stability of DAC can be ensured. Quality control includes raw material testing, production process monitoring, finished product testing, etc. to ensure that each DAC meets the specification requirements.

In general, the production process of DAC is a complex and rigorous process that requires the support of various technologies and equipment. Only through strict process control and quality management can high-quality and stable DAC products be produced to meet the needs of various applications. In the future, with the continuous development of technology, the production process of DAC will continue to improve to meet the market demand for high-performance and high-stability DAC products.