Important Product Categories of Wirewound Resistors

I. Introduction

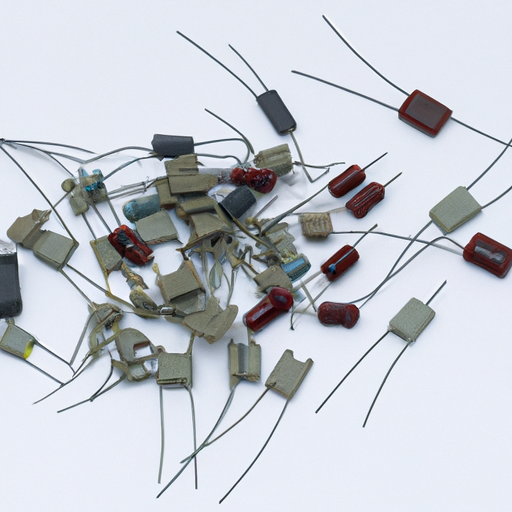

Wirewound resistors are a fundamental component in electronic circuits, known for their reliability and precision. These resistors are constructed by winding a wire around a core, typically made of ceramic or another insulating material, which allows them to handle higher power levels and provide accurate resistance values. Their importance in various applications, from industrial machinery to consumer electronics, cannot be overstated. This article aims to explore the key product categories of wirewound resistors, their applications, factors influencing their selection, and future trends in this technology.

II. Basic Principles of Wirewound Resistors

A. Construction and Materials

Wirewound resistors are primarily made from a resistive wire, which can be composed of materials such as nickel-chromium or copper-nickel. These materials are chosen for their ability to provide stable resistance values and withstand high temperatures. The wire is wound around a non-conductive core, often made of ceramic, which serves to insulate the wire and dissipate heat generated during operation. The choice of insulating materials is crucial, as it affects the resistor's performance and longevity.

B. Working Principle

The operation of wirewound resistors is based on Ohm's Law, which states that the current flowing through a conductor between two points is directly proportional to the voltage across the two points and inversely proportional to the resistance. As current flows through the wire, it generates heat due to its resistance. This heat must be effectively dissipated to prevent damage to the resistor and ensure reliable operation.

III. Key Product Categories of Wirewound Resistors

A. Fixed Wirewound Resistors

Fixed wirewound resistors are the most common type, providing a specific resistance value that does not change. They are widely used in applications where precise resistance is required, such as in voltage dividers and current limiting circuits.

**Advantages:**

- High stability and accuracy

- Capable of handling high power levels

**Disadvantages:**

- Limited flexibility, as the resistance value cannot be adjusted

B. Adjustable Wirewound Resistors (Potentiometers)

Adjustable wirewound resistors, commonly known as potentiometers, allow users to change the resistance value as needed. They are often used in applications such as volume controls in audio equipment and tuning circuits.

**Advantages:**

- Versatile and user-friendly

- Can be adjusted to meet specific circuit requirements

**Disadvantages:**

- Generally less stable than fixed resistors

- Mechanical wear can affect performance over time

C. High-Power Wirewound Resistors

High-power wirewound resistors are designed to handle significant amounts of power, making them ideal for applications such as power supplies and motor control systems. These resistors are built to dissipate heat effectively, ensuring they operate safely under high load conditions.

**Advantages:**

- Excellent heat dissipation

- Suitable for high-current applications

**Disadvantages:**

- Larger size compared to standard resistors

- Higher cost due to specialized construction

D. Precision Wirewound Resistors

Precision wirewound resistors are engineered for applications requiring high accuracy and low tolerance levels. They are commonly used in measurement and calibration equipment, where even slight variations in resistance can lead to significant errors.

**Advantages:**

- Extremely accurate and stable

- Low temperature coefficient

**Disadvantages:**

- More expensive than standard resistors

- Limited availability in certain resistance values

E. Specialty Wirewound Resistors

Specialty wirewound resistors are designed for specific applications, such as high-frequency circuits or environments with extreme temperatures. These resistors may incorporate unique materials or designs to meet the demands of specialized applications.

**Advantages:**

- Tailored for specific needs

- Can offer enhanced performance in niche applications

**Disadvantages:**

- Often more costly due to specialized manufacturing

- May have limited availability

IV. Applications of Wirewound Resistors

A. Industrial Applications

Wirewound resistors play a crucial role in industrial settings, particularly in power supplies and motor control systems. They help regulate voltage and current, ensuring that machinery operates efficiently and safely.

B. Consumer Electronics

In consumer electronics, wirewound resistors are commonly found in audio equipment, where they help manage signal levels and prevent distortion. They are also used in home appliances, providing reliable performance in various electronic circuits.

C. Automotive Applications

In the automotive industry, wirewound resistors are essential components in engine control units and safety systems. They help manage electrical signals and ensure that critical systems function correctly, contributing to vehicle safety and performance.

D. Medical Devices

Wirewound resistors are used in medical devices, including diagnostic and therapeutic equipment. Their precision and reliability are vital in applications where accurate measurements and consistent performance are critical for patient safety.

V. Factors Influencing the Selection of Wirewound Resistors

When selecting wirewound resistors for a specific application, several factors must be considered:

A. Resistance Value and Tolerance

The required resistance value and tolerance level are primary considerations. Different applications may demand varying levels of precision, influencing the choice of resistor type.

B. Power Rating

The power rating indicates how much power the resistor can handle without overheating. It is essential to choose a resistor with an appropriate power rating for the intended application to ensure reliability.

C. Temperature Coefficient

The temperature coefficient measures how much the resistance changes with temperature. For applications sensitive to temperature variations, selecting a resistor with a low temperature coefficient is crucial.

D. Environmental Considerations

The operating environment can significantly impact resistor performance. Factors such as humidity, temperature extremes, and exposure to chemicals should be considered when selecting wirewound resistors.

E. Cost and Availability

Finally, cost and availability are practical considerations. While precision and performance are essential, budget constraints and the availability of specific resistor types can influence the final selection.

VI. Future Trends in Wirewound Resistor Technology

As technology continues to evolve, wirewound resistors are also undergoing significant changes.

A. Innovations in Materials and Manufacturing

Advancements in materials science are leading to the development of new wire and insulating materials that enhance performance and reliability. These innovations may result in resistors that can operate at higher temperatures or offer improved stability.

B. Increasing Demand for Miniaturization

The trend toward miniaturization in electronics is driving the demand for smaller, more compact wirewound resistors. Manufacturers are exploring ways to reduce the size of these components without compromising performance.

C. Integration with Smart Technologies

As smart technologies become more prevalent, wirewound resistors are being integrated into smart devices and systems. This integration allows for enhanced functionality and improved performance in various applications.

D. Sustainability and Eco-Friendly Practices

With growing awareness of environmental issues, there is an increasing focus on sustainability in resistor manufacturing. This includes using eco-friendly materials and processes to reduce the environmental impact of production.

VII. Conclusion

Wirewound resistors are a vital component in a wide range of electronic applications, offering reliability, precision, and versatility. Understanding the different product categories—fixed, adjustable, high-power, precision, and specialty wirewound resistors—can help engineers and designers select the right components for their specific needs. As technology advances, wirewound resistors will continue to evolve, adapting to new challenges and opportunities in the electronics industry. Their importance in both current and future applications underscores the need for ongoing research and development in this essential field.

VIII. References

1. "Wirewound Resistors: Principles and Applications," Journal of Electronic Components, 2022.

2. "Advancements in Resistor Technology," Electronics Weekly, 2023.

3. "The Role of Resistors in Modern Electronics," IEEE Transactions on Industrial Electronics, 2023.

4. "Sustainable Practices in Electronic Component Manufacturing," Environmental Science & Technology, 2023.

This blog post provides a comprehensive overview of wirewound resistors, their categories, applications, and future trends, making it a valuable resource for anyone interested in understanding this essential electronic component.

Important Product Categories of Wirewound Resistors

I. Introduction

Wirewound resistors are a fundamental component in electronic circuits, known for their reliability and precision. These resistors are constructed by winding a wire around a core, typically made of ceramic or another insulating material, which allows them to handle higher power levels and provide accurate resistance values. Their importance in various applications, from industrial machinery to consumer electronics, cannot be overstated. This article aims to explore the key product categories of wirewound resistors, their applications, factors influencing their selection, and future trends in this technology.

II. Basic Principles of Wirewound Resistors

A. Construction and Materials

Wirewound resistors are primarily made from a resistive wire, which can be composed of materials such as nickel-chromium or copper-nickel. These materials are chosen for their ability to provide stable resistance values and withstand high temperatures. The wire is wound around a non-conductive core, often made of ceramic, which serves to insulate the wire and dissipate heat generated during operation. The choice of insulating materials is crucial, as it affects the resistor's performance and longevity.

B. Working Principle

The operation of wirewound resistors is based on Ohm's Law, which states that the current flowing through a conductor between two points is directly proportional to the voltage across the two points and inversely proportional to the resistance. As current flows through the wire, it generates heat due to its resistance. This heat must be effectively dissipated to prevent damage to the resistor and ensure reliable operation.

III. Key Product Categories of Wirewound Resistors

A. Fixed Wirewound Resistors

Fixed wirewound resistors are the most common type, providing a specific resistance value that does not change. They are widely used in applications where precise resistance is required, such as in voltage dividers and current limiting circuits.

**Advantages:**

- High stability and accuracy

- Capable of handling high power levels

**Disadvantages:**

- Limited flexibility, as the resistance value cannot be adjusted

B. Adjustable Wirewound Resistors (Potentiometers)

Adjustable wirewound resistors, commonly known as potentiometers, allow users to change the resistance value as needed. They are often used in applications such as volume controls in audio equipment and tuning circuits.

**Advantages:**

- Versatile and user-friendly

- Can be adjusted to meet specific circuit requirements

**Disadvantages:**

- Generally less stable than fixed resistors

- Mechanical wear can affect performance over time

C. High-Power Wirewound Resistors

High-power wirewound resistors are designed to handle significant amounts of power, making them ideal for applications such as power supplies and motor control systems. These resistors are built to dissipate heat effectively, ensuring they operate safely under high load conditions.

**Advantages:**

- Excellent heat dissipation

- Suitable for high-current applications

**Disadvantages:**

- Larger size compared to standard resistors

- Higher cost due to specialized construction

D. Precision Wirewound Resistors

Precision wirewound resistors are engineered for applications requiring high accuracy and low tolerance levels. They are commonly used in measurement and calibration equipment, where even slight variations in resistance can lead to significant errors.

**Advantages:**

- Extremely accurate and stable

- Low temperature coefficient

**Disadvantages:**

- More expensive than standard resistors

- Limited availability in certain resistance values

E. Specialty Wirewound Resistors

Specialty wirewound resistors are designed for specific applications, such as high-frequency circuits or environments with extreme temperatures. These resistors may incorporate unique materials or designs to meet the demands of specialized applications.

**Advantages:**

- Tailored for specific needs

- Can offer enhanced performance in niche applications

**Disadvantages:**

- Often more costly due to specialized manufacturing

- May have limited availability

IV. Applications of Wirewound Resistors

A. Industrial Applications

Wirewound resistors play a crucial role in industrial settings, particularly in power supplies and motor control systems. They help regulate voltage and current, ensuring that machinery operates efficiently and safely.

B. Consumer Electronics

In consumer electronics, wirewound resistors are commonly found in audio equipment, where they help manage signal levels and prevent distortion. They are also used in home appliances, providing reliable performance in various electronic circuits.

C. Automotive Applications

In the automotive industry, wirewound resistors are essential components in engine control units and safety systems. They help manage electrical signals and ensure that critical systems function correctly, contributing to vehicle safety and performance.

D. Medical Devices

Wirewound resistors are used in medical devices, including diagnostic and therapeutic equipment. Their precision and reliability are vital in applications where accurate measurements and consistent performance are critical for patient safety.

V. Factors Influencing the Selection of Wirewound Resistors

When selecting wirewound resistors for a specific application, several factors must be considered:

A. Resistance Value and Tolerance

The required resistance value and tolerance level are primary considerations. Different applications may demand varying levels of precision, influencing the choice of resistor type.

B. Power Rating

The power rating indicates how much power the resistor can handle without overheating. It is essential to choose a resistor with an appropriate power rating for the intended application to ensure reliability.

C. Temperature Coefficient

The temperature coefficient measures how much the resistance changes with temperature. For applications sensitive to temperature variations, selecting a resistor with a low temperature coefficient is crucial.

D. Environmental Considerations

The operating environment can significantly impact resistor performance. Factors such as humidity, temperature extremes, and exposure to chemicals should be considered when selecting wirewound resistors.

E. Cost and Availability

Finally, cost and availability are practical considerations. While precision and performance are essential, budget constraints and the availability of specific resistor types can influence the final selection.

VI. Future Trends in Wirewound Resistor Technology

As technology continues to evolve, wirewound resistors are also undergoing significant changes.

A. Innovations in Materials and Manufacturing

Advancements in materials science are leading to the development of new wire and insulating materials that enhance performance and reliability. These innovations may result in resistors that can operate at higher temperatures or offer improved stability.

B. Increasing Demand for Miniaturization

The trend toward miniaturization in electronics is driving the demand for smaller, more compact wirewound resistors. Manufacturers are exploring ways to reduce the size of these components without compromising performance.

C. Integration with Smart Technologies

As smart technologies become more prevalent, wirewound resistors are being integrated into smart devices and systems. This integration allows for enhanced functionality and improved performance in various applications.

D. Sustainability and Eco-Friendly Practices

With growing awareness of environmental issues, there is an increasing focus on sustainability in resistor manufacturing. This includes using eco-friendly materials and processes to reduce the environmental impact of production.

VII. Conclusion

Wirewound resistors are a vital component in a wide range of electronic applications, offering reliability, precision, and versatility. Understanding the different product categories—fixed, adjustable, high-power, precision, and specialty wirewound resistors—can help engineers and designers select the right components for their specific needs. As technology advances, wirewound resistors will continue to evolve, adapting to new challenges and opportunities in the electronics industry. Their importance in both current and future applications underscores the need for ongoing research and development in this essential field.

VIII. References

1. "Wirewound Resistors: Principles and Applications," Journal of Electronic Components, 2022.

2. "Advancements in Resistor Technology," Electronics Weekly, 2023.

3. "The Role of Resistors in Modern Electronics," IEEE Transactions on Industrial Electronics, 2023.

4. "Sustainable Practices in Electronic Component Manufacturing," Environmental Science & Technology, 2023.

This blog post provides a comprehensive overview of wirewound resistors, their categories, applications, and future trends, making it a valuable resource for anyone interested in understanding this essential electronic component.